Contact: +49 2772 58350-0 | info@ghs-vakuumtechnik.de

VACUUM – DRYING OVENS

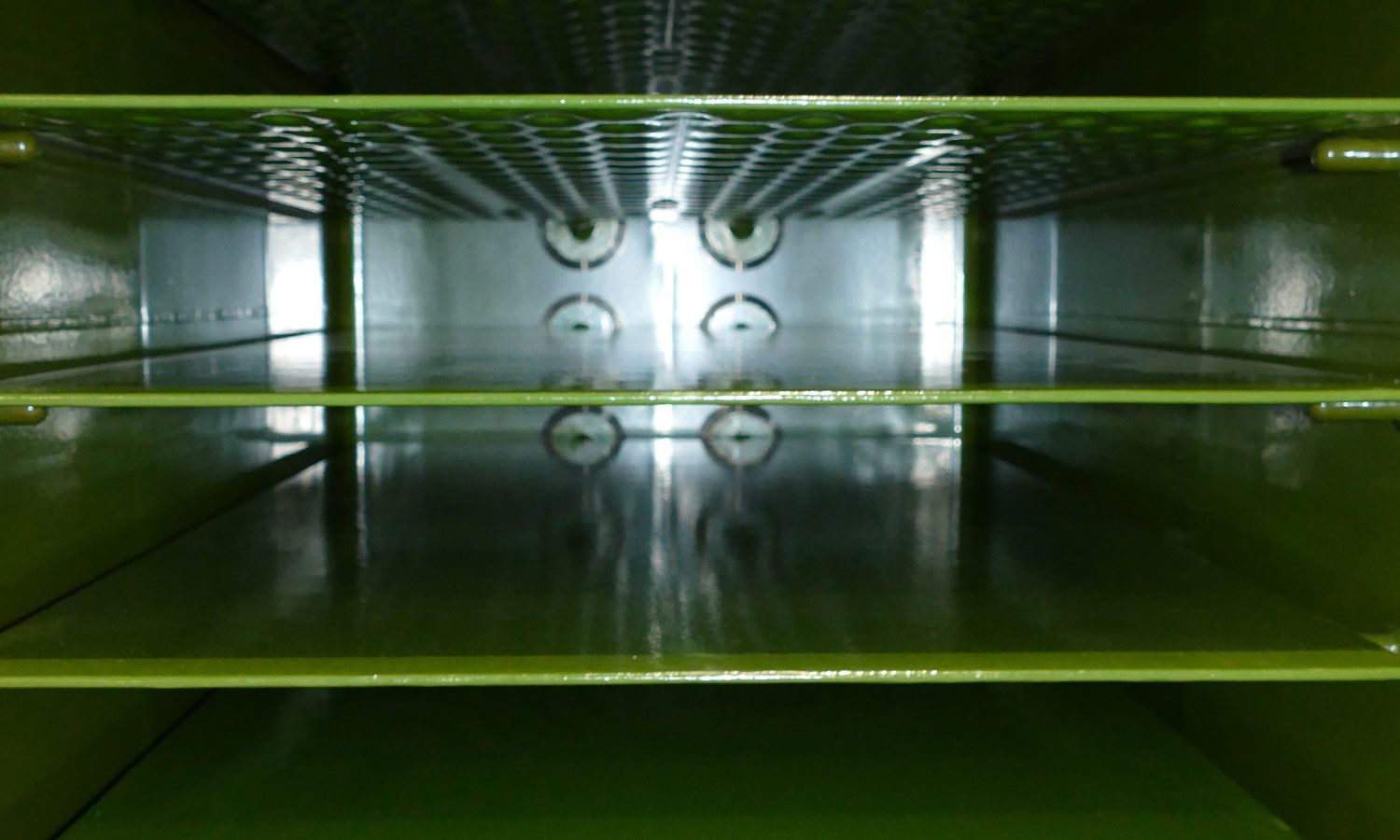

VDS-S30 Vacuum drying oven (VTS) and vacuum circulating air drying oven (VUTS) are tried and tested standard systems with useful equipment options. Ideal for drying anode or cathode coils in battery production, among other applications.

VACUUM – DRYING OVENS

VDS-S30 Vacuum drying oven (VTS) and vacuum circulating air drying oven (VUTS) are tried and tested standard systems with useful equipment options. Ideal for drying anode or cathode coils in battery production, among other applications.

DEHUMIDIFICATION AND DRYING PROCESS UNDER VACUUM

PRODUCT-ADAPTED HEATING

VARIOUS LOADING OPTIONS

HIGH STANDARDIZATION

TECHNICAL DATA

Vacuum – drying ovens

Total capacity | up to 6,000 L |

Floor space size | from 0.5 to 200 m² |

Operating temperature | up to 400 °C |

Operating vacuum | < 10 E-3 mbar |

Useful volume | typically 70% – 80% |

Condensers | up to 100 kg H2O/h |

PRODUCT DESCRIPTION

VUTS (2 versions):

Version 1:

- Cost-effective equipment with electric heating inside the vacuum drying chamber

- Heating using the circulation/air recirculation method by heat transfer from the electric heating to the heat transfer medium “air” or “inert gas”

- Indirect cooling possible by means of separate cooling/heat exchangers within the vacuum drying chamber as well as additional cooling machine or on-site cold water supply

Version 2:

- Equipment with separate temperature control unit for the heat transfer medium water or oil, up to 400 °C depending on the application

- Heating using the circulation/air recirculation method by heat transfer from the heated vacuum chamber walls to the heat transfer medium “air” or “gas”.

- Direct re-cooling is possible by means of an additional heat exchanger integrated in the temperature control unit. This requires an additional chiller or an on-site cold water supply.

VTS (3 Versions):

Version 1:

- Cost-effective design without heating, for “simple” vacuum drying without considerable accumulation of condensate.

Version 2:

- Heating of the floors/shelves and/or chamber walls with heat transfer to the material to be dried by means of a separate temperature control unit for heat transfer media “water” or “oil”, up to 400 °C depending on the application. Direct electric heating of the chamber walls and/or floors/shelves up to 450 °C, without active re-cooling, is also possible.

- Special models of the temperature control units for heat transfer from any steam present on the customer side to the heat transfer medium “water” or “oil”, including any necessary additional electric heating, are also possible.

- Temperature control can also be provided by the customer according to specification.

- Direct re-cooling by means of an additional heat exchanger integrated in the temperature control unit is possible. This may require an additional chiller or on-site cold water supply.

Version 3:

- Versions 1 and 2 can also be delivered with special coatings for chemically aggressive drying products.